Exploring non-ferrous copper valve parts: the "invisible hero" in the industrial field

一、引言:阀门零部件的 “铜” 心魅力 First, introduction: the "copper" heart charm of valve parts

In the huge system of the industrial field, valves are like the valves in our blood vessels, controlling the direction and amount of all kinds of fluids. Among the many materials for valve parts, copper products, with their special charm, have become the top choice in many key fields.

Just imagine, on the oil extraction platforms thousands of meters deep in the sea, in the environment of high pressure and strong corrosion, copper valve parts keep working quietly to make sure the oil is transported steadily. Or in the heating systems in cities, countless copper valves adjust the flow of hot water precisely to send warmth to thousands of families. These scenes that seem ordinary actually show the extraordinary value of copper valve parts everywhere.

Today, let's explore together the secrets of non-ferrous metal copper products in valve-related parts.

二、铜制阀门零部件大揭秘

Two, copper valve parts revealed

(一)常见种类大盘点

(1) General inventory of common types

- 闸阀:闸阀的结构犹如一位坚守岗位的忠诚卫士,主要由阀体、阀盖、闸板、阀杆、阀座和密封填料等构成 。其工作原理是通过阀杆的旋转,带动闸板垂直于流体方向上下移动,实现阀门的开启与关闭。当闸板完全开启时,流体几乎可以毫无阻碍地通过,如同宽阔的河道畅行无阻,具有极低的流动阻力;而当闸板关闭,便能可靠地截断流体。因其出色的密封性和大通径流通能力,在自来水厂、污水处理厂等大型流体输送系统中广泛应用。在自来水厂的主输水管道上,闸阀能够在需要维修或调整时,精准截断水流,保障后续工作的顺利进行。

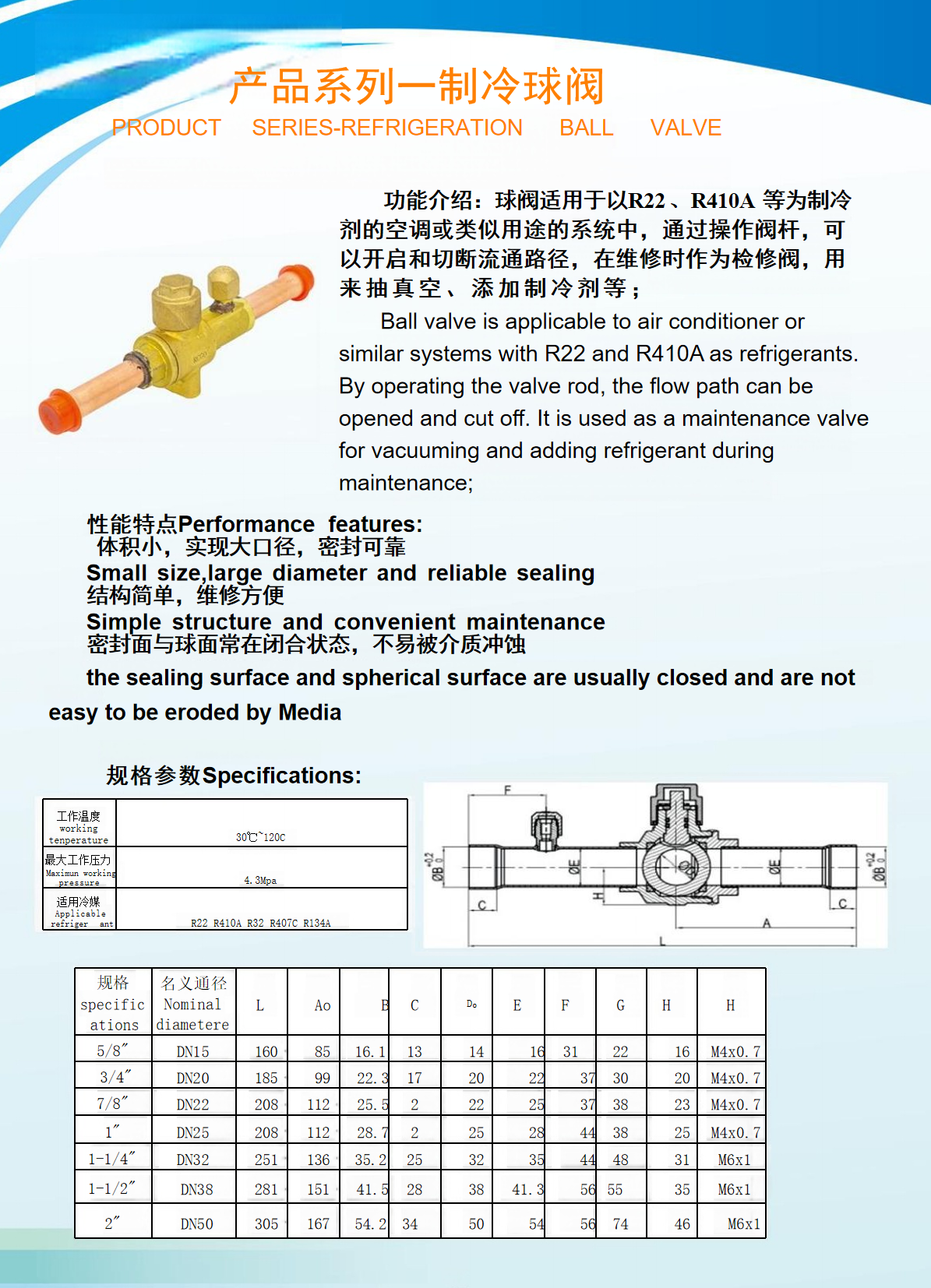

- 球阀:球阀宛如一个灵活的旋转舞者,核心部件为球体,球体上有圆形的通孔。工作时,只需旋转阀杆 90 度,球体的通孔与管道对齐,阀门开启,流体顺利通过;反之,球体转动使通孔与管道错开,阀门关闭。其结构简单、操作便捷,开关迅速,且流体阻力小。在家庭的燃气管道中,球阀能快速切断气源,保障家庭用气安全;在化工领域,对于一些需要快速启闭的腐蚀性介质管道,球阀凭借其耐腐蚀的特性,也能稳定发挥作用。

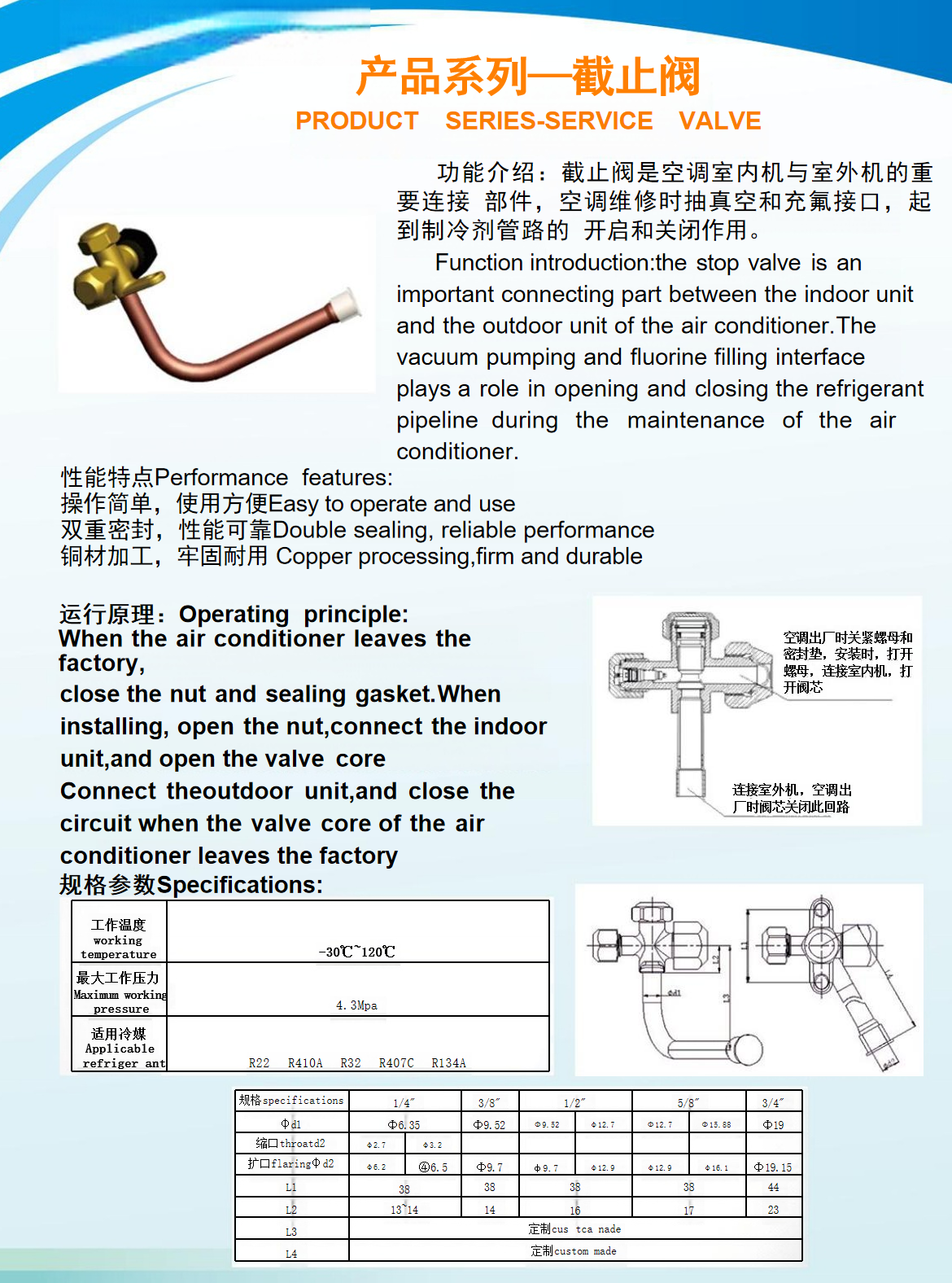

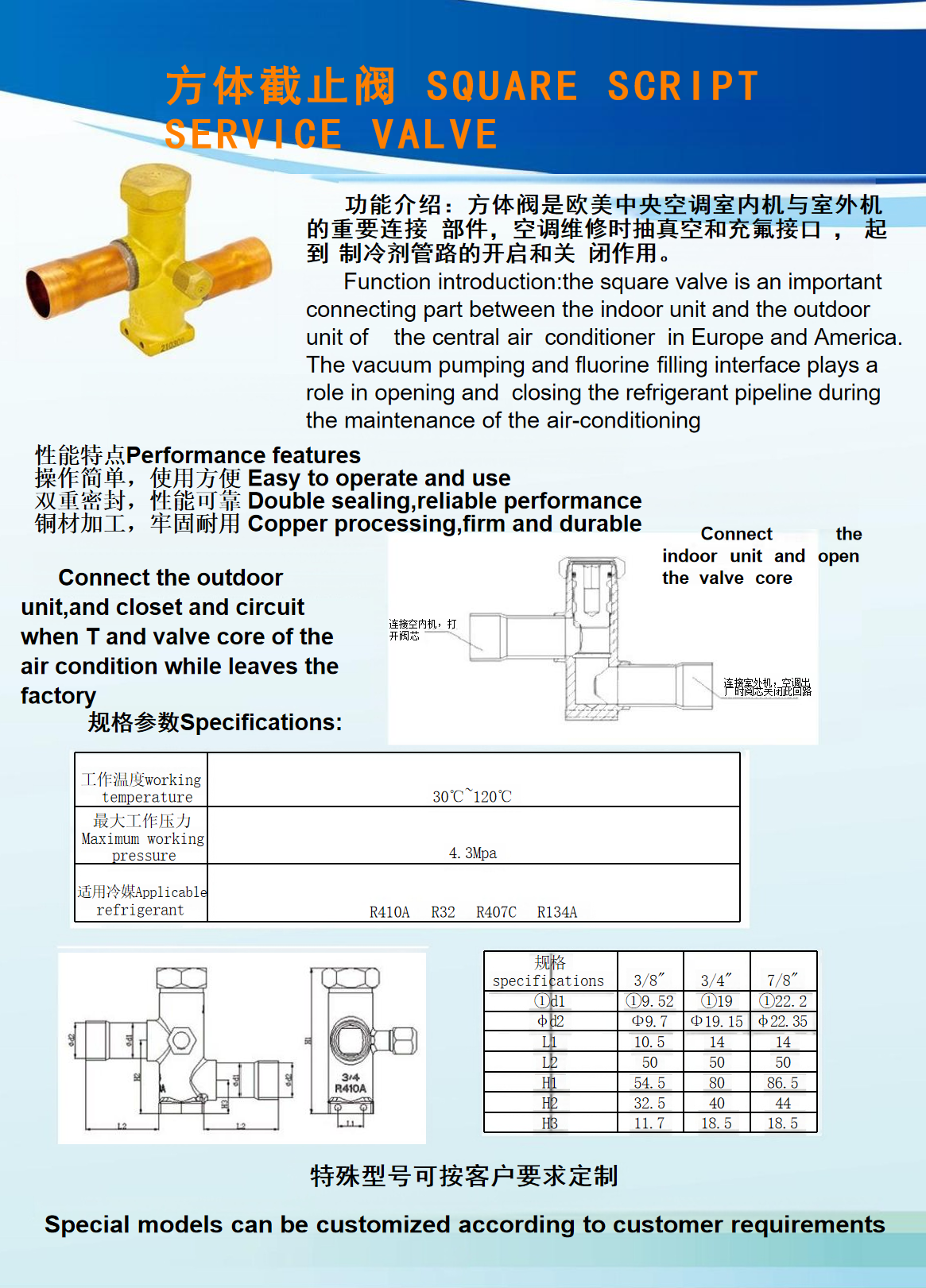

- 截止阀:截止阀的设计就像一个严格的关卡,由阀体、阀瓣、阀杆、阀座等组成。阀瓣沿着阀杆的轴线做升降运动,以控制流体的通断 。当阀瓣上升,流体可以通过;阀瓣下降,紧密贴合阀座,截断流体。它具有良好的调节流量功能,能较为精准地控制流体的流量大小。在供暖系统中,截止阀可根据实际需求,调节热水的流量,从而控制室内温度。

- 止回阀:止回阀如同单向通行的交通规则执行者,只允许流体单向流动 。常见的有旋启式和升降式两种。旋启式止回阀的阀瓣像一扇可以旋转的门,依靠流体的压力推动阀瓣开启,当流体反向流动时,阀瓣在自身重力和反向压力作用下迅速关闭,阻止流体倒流;升降式止回阀的阀瓣则是沿着阀杆做升降运动实现开启和关闭。在水泵的出口管道上,止回阀能有效防止停泵时水的倒流,保护水泵不受损坏。

Gate valve: The structure of a gate valve is like a loyal guard on duty, mainly composed of the valve body, valve cover, gate, valve stem, valve seat and packing material. Its working principle is that by rotating the valve stem, the gate moves up and down perpendicularly to the flow direction, achieving the opening and closing of the valve. When the gate is fully open, the fluid can pass through almost without any hindrance, just like a wide river flowing smoothly, with extremely low flow resistance; when the gate is closed, it can reliably cut off the fluid. Due to its excellent sealing performance and large diameter flow capacity, it is widely used in large fluid transmission systems such as waterworks and sewage treatment plants. On the main water supply pipeline of a waterworks, the gate valve can precisely cut off the water flow when maintenance or adjustment is needed, ensuring the smooth progress of subsequent work.

Ball valve: The ball valve is like a flexible rotating dancer, with the ball as its core component, which has a circular through hole. During operation, simply rotating the valve stem 90 degrees aligns the through hole of the ball with the pipeline, opening the valve and allowing the fluid to pass smoothly; conversely, when the ball rotates to misalign the through hole with the pipeline, the valve closes. It has a simple structure, convenient operation, quick opening and closing, and low fluid resistance. In household gas pipelines, the ball valve can quickly cut off the gas source, ensuring the safety of household gas use; in the chemical industry, for some pipelines carrying corrosive media that require rapid opening and closing, the ball valve can also function stably due to its corrosion resistance.

Globe valve: The design of a globe valve is like a strict checkpoint, consisting of the valve body, disc, valve stem, valve seat, etc. The disc moves up and down along the axis of the valve stem to control the flow of the fluid. When the disc rises, the fluid can pass through; when the disc descends, it tightly fits the valve seat, cutting off the fluid. It has a good flow regulation function and can precisely control the flow rate of the fluid. In heating systems, the globe valve can adjust the flow rate of hot water according to actual needs, thereby controlling the indoor temperature.

Check valve: The check valve is like an enforcer of one-way traffic rules, allowing fluid to flow in only one direction. Common types include swing check valves and lift check valves. The disc of a swing check valve is like a rotating door, pushed open by the fluid pressure and quickly closing under the force of its own weight and reverse pressure when the fluid flows in the opposite direction; the disc of a lift check valve moves up and down along the valve stem to achieve opening and closing. On the outlet pipeline of a water pump, the check valve can effectively prevent the backflow of water when the pump stops, protecting the pump from damage.

(二)独特性能大放送

(2) Unique performance

- 优良的导热性:铜是热的良导体,其导热性能在众多金属中表现出色。以铜制的热交换器阀门为例,在空调系统的热交换过程中,铜制阀门能够迅速将热量传导出去,实现高效的热交换,确保空调系统稳定运行,为人们营造舒适的室内环境 。在工业领域的大型热交换设备中,铜制阀门的优良导热性使得热量能够快速传递,提高能源利用效率,降低能耗。

- 抗腐蚀性强:铜在许多介质中具有良好的化学稳定性,能有效抵抗水、气体以及部分化学物质的腐蚀。在海洋工程中,海水对金属具有极强的腐蚀性,但铜制阀门凭借其抗腐蚀性能,在海水淡化设备的管道系统中,长期稳定运行,保障淡化海水的顺利输送 。在化工行业的一些腐蚀性液体输送管道中,铜制阀门也能凭借自身优势,抵御介质侵蚀,减少维护和更换频率,降低企业运营成本。

- 高强度与耐压性:别看铜制阀门零部件外观精致,它们却拥有强大的抗压能力。经过特殊工艺处理后,铜合金制成的阀门能够承受较大的压力,确保在高压环境下,如石油天然气的长距离输送管道中,稳定可靠地控制流体 。在深海石油开采平台,高压环境下的铜制阀门需承受巨大的压力,但其高强度和耐压性,使其能够正常工作,保障石油开采的顺利进行。

- 易加工性:铜材料具有良好的可塑性,如同一块柔软的黏土,易于通过铸造、锻造、机械加工等多种工艺,被制成各种复杂形状和高精度要求的阀门零部件 。这使得阀门制造商能够根据不同的应用场景和需求,快速生产出定制化的产品。在一些小型阀门加工厂,通过简单的铸造工艺,就能将铜材料加工成各种形状的阀门,满足市场的多样化需求。

- 环保健康:铜是一种天然的环保材料,不会像一些其他金属那样在使用过程中释放有害物质,对人体健康和环境造成危害 。在饮用水输送系统中,铜制阀门不仅能确保水质不受污染,而且其微量的铜离子还有一定的杀菌作用,有助于保障饮用水的安全。在食品加工行业,铜制阀门也因其环保健康的特性,被广泛应用于食品流体的输送管道中,确保食品的安全和卫生。

Excellent thermal conductivity: Copper is an excellent thermal conductor, and its thermal conductivity is outstanding among many metals. Take copper-made heat exchanger valves as an example. During the heat exchange process in air conditioning systems, copper valves can quickly conduct heat away, achieving efficient heat exchange and ensuring the stable operation of the air conditioning system, creating a comfortable indoor environment for people. In large heat exchange equipment in the industrial field, the excellent thermal conductivity of copper valves enables rapid heat transfer, improving energy utilization efficiency and reducing energy consumption.

Strong corrosion resistance: Copper has good chemical stability in many media and can effectively resist corrosion by water, gases, and some chemical substances. In marine engineering, seawater has extremely strong corrosiveness to metals, but copper valves, with their strong corrosion resistance, can operate stably for a long time in the pipeline systems of seawater desalination equipment, ensuring the smooth transportation of desalinated water. In some corrosive liquid pipelines in the chemical industry, copper valves can also resist medium erosion, reduce maintenance and replacement frequency, and lower enterprise operating costs.

High strength and pressure resistance: Despite their delicate appearance, copper valve components have strong pressure resistance. After special processing, copper alloy valves can withstand high pressure, ensuring stable and reliable control of fluids in high-pressure environments, such as long-distance pipelines for oil and natural gas transportation. On deep-sea oil drilling platforms, copper valves in high-pressure environments can withstand huge pressure, and their high strength and pressure resistance enable them to work normally, ensuring the smooth progress of oil drilling.

Easy processability: Copper materials have good plasticity, like a soft clay, and can be easily processed into various complex shapes and high-precision valve components through casting, forging, mechanical processing, and other techniques. This enables valve manufacturers to quickly produce customized products according to different application scenarios and requirements. In some small valve processing plants, copper materials can be processed into various shapes of valves through simple casting processes, meeting the diverse demands of the market.

Environmental friendliness and health: Copper is a natural and environmentally friendly material that does not release harmful substances during use, unlike some other metals, which can cause harm to human health and the environment. In drinking water delivery systems, copper valves not only ensure the water quality is not contaminated but also have a certain bactericidal effect due to trace copper ions, helping to ensure the safety of drinking water. In the food processing industry, copper valves are widely used in food fluid pipelines due to their environmental friendliness and health benefits, ensuring the safety and hygiene of food.

三、在各领域的精彩表现

3. Excellent performance in various fields

(一)工业生产:稳定运行的保障

(1) Industrial production: guarantee of stable operation

(二)建筑领域:舒适生活的支撑

(2) Construction field: support for comfortable life

In the water supply and drainage system of the building, copper valve parts are the key to ensure the safety and smooth water use. In the water supply system of high-rise buildings, due to the large water pressure, the pressure resistance and sealing of the valve are very high. The copper stop valve and gate valve can withstand high water pressure, effectively control the flow of water, to ensure a stable water supply to each floor. At the same time, its good corrosion resistance can prevent water pollution caused by valve corrosion and ensure the safety of drinking water for residents. In the kitchen and bathroom of the family, the copper faucet valve, flexible operation, good sealing, can easily control the size of the water flow, bringing convenience to daily life. In the heating system, copper valves are indispensable. In the northern winter, the hot water of central heating is transported to thousands of households through pipelines, and the copper temperature control valve can automatically adjust the flow of hot water according to the change of indoor temperature, so as to achieve accurate control of indoor temperature. When the indoor temperature is too high, the temperature control valve automatically reduces the hot water flow. When the temperature is too low, the flow rate is increased to create a comfortable indoor environment for people. Moreover, the excellent thermal conductivity of the copper valve helps the rapid transfer of heat and improves the heating efficiency.

(三)其他领域:无处不在的身影

(3) Other areas: ubiquitous figure

In the garden irrigation system, in order to achieve accurate and efficient irrigation, copper valves play an important role. With the intelligent control system, the solenoid valve can automatically control the flow and time of irrigation water according to soil moisture, weather conditions and other factors. The copper material ensures the long-term stable operation of the valve in a humid environment, which is not easy to rust and corrosion, ensures the normal operation of the irrigation system, and provides suitable water for the growth of garden plants. In the field of shipbuilding, ships are faced with the challenge of high humidity and high salt corrosion in the Marine environment. Because of its excellent corrosion resistance, copper valve parts are the first choice for Marine piping systems. In the sea water cooling system and fuel supply system of the ship, the copper ball valve and check valve can reliably control the flow of fluid, ensure the normal operation of the ship's equipment, and provide a solid guarantee for the safe navigation of the ship.

四、贸易市场的风云变幻

Fourth, changes in the trade market

竞争态势剖析

Analysis of competitive situation

At the same time, a large number of small and medium-sized enterprises are competing fiercely in the middle and low-end market. These companies with flexible business strategies and cost advantages to meet the market's broad demand for universal copper valve parts. However, with the increasingly fierce market competition and the fluctuation of raw material prices, smes are faced with multiple challenges such as cost control and technological innovation. In order to stand out in the competition, some small and medium-sized enterprises have begun to strengthen investment in technology research and development, cooperate with universities and scientific research institutions, introduce advanced production processes, improve product quality, and gradually move toward the middle and high-end market.

Looking at the international market, China's copper valve parts enterprises in the global competition, both have their own unique advantages, but also face many serious challenges. In terms of advantages, China's complete industrial system enables enterprises to realize the collaborative operation of the whole industrial chain from raw material procurement to product production, effectively reduce production costs, and have strong competitiveness in price. At the same time, after years of technology accumulation and personnel training, the gap between Chinese enterprises and the international advanced level in product quality and performance has been narrowing, and it can meet the diversified needs of the international market for copper valve parts.

五、选择与使用的智慧锦囊

5. Wisdom of choice and use

(一)挑选攻略

- 依控制功能而定:若需要精确调节流量,截止阀是不错的选择,其阀瓣的升降运动能细腻控制流体通过量;要是追求快速切断或导通流体,球阀的 90 度旋转启闭方式则高效便捷;而当需要可靠截断流体,闸阀凭借其闸板的垂直移动,密封性极佳,能胜任这一任务;若是防止流体倒流,止回阀便是专为这一功能设计的。

- 结合工况条件考量:从压力方面来看,明确管道系统的工作压力,选择公称压力适配的铜制阀门零部件,确保在高压环境下也能安全稳定运行。例如,在石油化工的高压管道中,就需选用能承受相应高压的铜阀。温度也是关键因素,不同的铜合金材料在高低温环境下的性能表现各异。对于高温工况,某些特殊铜合金制成的阀门能保持良好的机械性能;而在低温环境,要避免铜制阀门因低温变脆影响使用。介质的特性同样不容忽视,若是腐蚀性介质,铜的抗腐蚀性能虽好,但不同类型的腐蚀环境仍需针对性选择合适的铜合金材质。

- 匹配安装结构挑选:管道系统的安装结构多种多样,常见的有管螺纹连接、法兰连接、焊接连接等。管螺纹连接的阀门,要注意内螺纹和外螺纹的规格匹配,外螺纹一般为圆锥管螺纹,以确保连接紧密;法兰连接的阀门,其法兰的规格尺寸、公称压力都要与管道的法兰一致,安装时螺栓的紧固也需均匀用力,保证密封效果;焊接连接的阀门,对焊接工艺要求较高,要确保焊接质量,避免出现泄漏点。

(1) Choose a guideline

Depending on the control function: if you need to accurately adjust the flow rate, the globe valve is a good choice, and the lifting movement of the valve disc can fine-control the flow of fluid; If you want to quickly cut off or channel the fluid, the 90-degree rotary opening and closing of the ball valve is efficient and convenient; When reliable fluid cut-off is required, the gate valve, with its vertical movement of the gate plate and excellent sealing, is up to the task; If it prevents fluid backflow, check valves are designed for this function.

Considering the working conditions: from the pressure point of view, the working pressure of the pipeline system is clear, and the copper valve parts with nominal pressure are selected to ensure safe and stable operation under high pressure environment. For example, in the high-pressure pipeline of the petrochemical industry, it is necessary to choose a copper valve that can withstand the corresponding high pressure. Temperature is also a key factor, and different copper alloys behave differently at high and low temperatures. For high temperature conditions, some valves made of special copper alloys can maintain good mechanical properties; In the low temperature environment, it is necessary to avoid the use of copper valves due to low temperature brittleness. The characteristics of the medium can not be ignored, if the corrosive medium, the corrosion resistance of copper is good, but different types of corrosion environment still need to choose the appropriate copper alloy material.

Selection of matching installation structure: there are a variety of installation structures of pipeline systems, common pipe threaded connections, flange connections, welded connections, etc. Pipe thread connected valve, pay attention to the specifications of the internal thread and the external thread match, the external thread is generally taper pipe thread, to ensure that the connection is tight; Flange connected valve, the size of the flange, nominal pressure should be consistent with the pipe flange, the installation of bolts fastening also need uniform force to ensure the sealing effect; Welded valves have high requirements for welding processes, and the quality of welding should be ensured to avoid leakage points.

(二)安装要点

- 管螺纹连接:内螺纹可以是圆柱管螺纹或圆锥管螺纹,外螺纹必须是圆锥管螺纹 。连接时,要确保螺纹清洁、无杂质,可适当涂抹密封胶增强密封性。安装旋紧时,务必扳钳该螺纹同端的六角或八角部位,切勿扳钳阀门另一端,防止阀门因受力不均而变形。对于内螺纹连接的闸阀,要严格控制管端外螺纹的长度尺寸,避免管端过量旋入,顶压闸阀管螺纹内端面,致使阀座变形,影响阀门的密封性。

- 法兰连接:阀门的法兰与管端的法兰,不仅规格尺寸要完全一致,公称压力也必须匹配 。安装前,检查法兰密封面是否平整、有无损伤,密封垫片要正确放置。在拧紧螺栓时,应按照对角线顺序,逐步均匀地施加扭矩,确保法兰连接紧密,防止泄漏。

- 焊接连接:焊接前,需对阀门和管道的焊接部位进行清洁和预处理,去除油污、铁锈等杂质 。选择合适的焊接材料和焊接工艺,由专业焊工进行操作。焊接过程中,要控制好焊接电流、电压和焊接速度,确保焊缝质量。焊接完成后,对焊缝进行无损检测,如射线检测、超声波检测等,确保无焊接缺陷。

(2) Installation points

Pipe thread connection: The internal thread can be cylindrical pipe thread or conical pipe thread, and the external thread must be conical pipe thread. When connecting, ensure that the thread is clean and free of impurities, and apply sealant appropriately to enhance the sealing. When installing and tightening, be sure to wrench the hexagonal or octagonal part at the same end of the thread, and do not wrench the other end of the valve to prevent the valve from deformation due to uneven force. For the gate valve with internal thread connection, the length and size of the external thread of the pipe end should be strictly controlled to avoid excessive screwing of the pipe end, and the internal end face of the pipe thread of the gate valve should be pressed, resulting in the deformation of the seat and affecting the sealing of the valve.

Flange connection: The flange of the valve and the flange of the pipe end, not only the specification and size should be completely consistent, but the nominal pressure must also match. Before installation, check whether the sealing surface of the flange is smooth and there is no damage, and the sealing gasket should be placed correctly. When tightening bolts, torque should be applied gradually and evenly in a diagonal sequence to ensure tight flange connection and prevent leakage.

Welding connection: Before welding, clean and pretreat the welding parts of valves and pipelines to remove impurities such as oil and rust. Select the appropriate welding materials and welding processes, and operate by professional welders. In the welding process, the welding current, voltage and welding speed should be controlled to ensure the quality of the weld. After the welding is completed, non-destructive testing is carried out on the weld, such as X-ray testing, ultrasonic testing, etc., to ensure that there are no welding defects.

(三)使用维护秘籍

- 正确使用方法:在开启和关闭阀门时,动作要平稳、缓慢,避免快速猛力操作,防止对阀门内部结构造成冲击损坏 。尤其是球阀和闸阀,不宜部分开启做节流使用,因为部分开启时,流体的冲刷会加剧闸板和球体密封面的磨损,当介质含有杂质时,这种冲蚀作用更为严重。对于有明确介质流向要求的阀门,一定要严格按照规定方向安装和使用,确保阀门正常工作。

- 日常维护保养:定期对铜制阀门零部件进行清洁,去除表面的灰尘、油污和杂质,保持阀门外观整洁 。同时,检查阀门的连接部位是否松动,如有松动及时紧固。对于阀杆等活动部件,要定期涂抹适量的润滑剂,减少摩擦,保证阀门操作灵活。还要关注阀门的密封性能,若发现有泄漏现象,及时查找原因并进行修复。例如,对于截止阀、闸阀,若阀杆处出现泄漏,可适当拧紧填料处的压紧螺母,但注意用力要适度,以不漏水为限。

- 定期检查与维修:建立定期检查制度,对铜制阀门的整体性能进行评估 。检查阀门的密封面是否磨损、腐蚀,阀座是否有松动,阀杆是否变形等。对于一些关键部位的阀门,还可借助专业检测设备进行无损检测。一旦发现问题,及时进行维修或更换零部件。在维修过程中,要使用原厂配件或符合质量标准的替代配件,确保维修后的阀门性能可靠。

(3) Maintenance Secrets

Correct usage: When opening and closing valves, movements should be smooth and slow to avoid rapid and forceful operations that may cause damage to the internal structure of the valve. Especially for ball valves and gate valves, they should not be partially opened for throttling purposes. When partially opened, the fluid's erosion will accelerate the wear of the gate and ball sealing surfaces. This erosion is even more severe when the medium contains impurities. For valves with specified medium flow directions, they must be installed and used strictly in accordance with the specified direction to ensure normal operation.

Daily maintenance: Regularly clean the copper valve components to remove surface dust, oil stains, and impurities, keeping the valve appearance clean. At the same time, check if the valve connection parts are loose and tighten them if necessary. For moving parts such as the valve stem, apply an appropriate amount of lubricant regularly to reduce friction and ensure smooth operation. Also, pay attention to the valve's sealing performance. If leakage is detected, promptly identify the cause and carry out repairs. For example, if leakage occurs at the valve stem of a globe valve or gate valve, the packing gland nut can be tightened appropriately, but be careful not to apply excessive force to avoid water leakage.

Regular inspection and maintenance: Establish a regular inspection system to assess the overall performance of copper valves. Check if the sealing surfaces are worn or corroded, if the valve seats are loose, and if the valve stems are deformed. For critical valves, non-destructive testing can be conducted using professional inspection equipment. Once problems are identified, timely repairs or replacement of parts should be carried out. During the repair process, use original factory parts or alternative parts that meet quality standards to ensure reliable performance of the repaired valve.

六、未来展望:“铜” 领行业新潮流

Six, future outlook: "Copper" leading industry new trend

At the forefront of technological innovation, the wave of intelligence and digitalization is storming. Imagine that future copper valve components will be equipped with advanced sensors and intelligent control systems, they are like intelligent guardians, can real-time monitoring of fluid pressure, temperature, flow and other parameters, and automatically adjust the valve opening according to the preset program, to achieve accurate and efficient automatic control. This can not only greatly improve the efficiency and quality of industrial production, but also effectively reduce labor costs and energy consumption. For example, in the water supply and drainage system of intelligent buildings, copper intelligent valves can automatically adjust the water flow size according to the water demand at different times, and realize the rational use of water resources. At the same time, with the continuous progress of material science, the development of new copper alloy materials will inject more powerful properties into copper valve parts. These materials may have greater corrosion resistance, higher strength and better high temperature resistance, allowing them to operate stably in more extreme environments and further expand their applications.

From the perspective of market demand, with the continuous development of the global economy and the continuous advancement of infrastructure construction, the demand for copper valve parts in various fields will continue to grow. Under the guidance of the "double carbon" goal, the new energy industry is booming, and copper valve parts will play an indispensable role in the development and utilization of new energy sources such as solar energy, wind energy and water energy. Taking solar thermal power station as an example, copper valves are used to control the circulation of thermal oil, and its excellent thermal conductivity and stability ensure the efficient operation of the power generation system. In the field of construction, with the continuous improvement of people's requirements for quality of life, green buildings and intelligent buildings have become the development trend, which will bring broad market space for copper valve parts. Environmental health, excellent performance of copper valves, will become the building water supply and drainage, heating, ventilation and other systems of choice.

In addition, the in-depth implementation of the "Belt and Road" initiative has provided a rare historical opportunity for China's copper valve parts enterprises to expand the international market. The demand for infrastructure construction in countries along the line is strong, and Chinese enterprises are expected to win more orders in the international market with the advantages of product quality, cost performance and technical services, and further enhance China's copper valve parts and components in the global market share and influence.

七、结语:小零件,大作为

Conclusion: Small parts, big as

In the future, with the continuous innovation of technology and the continuous evolution of market demand, copper valve parts will usher in a broader space for development. Let us hope that these small parts can continue to bloom their own dazzling light on the stage of The Times and contribute more to the development of various industries.

latest news about HIGH ENERGY CAR

- CAR EV CAR EV MINI CAR

- Core products

- EVCS AC EV CHARGER DC EV CHARGER STATIONS EVC Service

- Accessory Auto parts Battery maintenance accessories Copper product parts

- special Service Membership Services Overseas marketing to store Industry solutions Distribution and agency Car purchase service Import and export services Battery recycling services Parking services Car rental services Road rescue services after-sale service User participation and rewards service network Data download

- Barter and Development Global Barter Research Center Global Development and Innovation Center KD/SKD joint construction technology output Automobile testing ground Vehicle Research Institute Docking with Automobile Associations of Various Countries Mineral resources sales category

- About us Company Profile Partners Videos Contact information News Campus recruitment Join Us WHY CHOOSE US

Return

Return