Safety Control

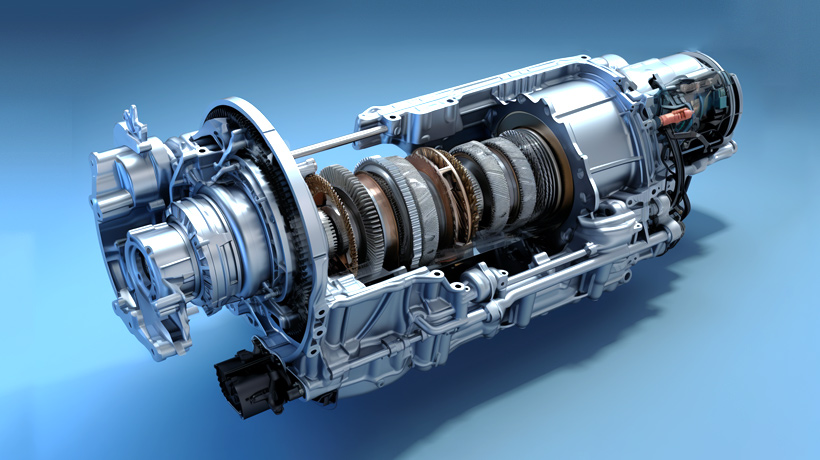

Safety control is crucial in the recycling process of new energy vehicles. To ensure safety, the following measures should be taken: use professional tools and equipment for disassembly and disposal, and strengthen employee safety training and education; Develop strict safety operating procedures, regularly inspect and maintain on-site safety, and equip professional emergency rescue teams and equipment. Through these measures, accidents and risks can be effectively reduced, ensuring the safety of employees and the environment. In short, the recycling process and technology of new energy vehicles are important links in the development of the entire industry. Through reasonable measures and methods such as vehicle disassembly, battery recycling, powertrain disassembly, body material classification, waste disposal, recycling, and safety control, the recycling rate and safety can be effectively improved, and the harm to the environment can be reduced. In the future, with the lack of progress in technology and the continuous deepening of application and promotion, the recycling process and technology of new energy vehicles will become increasingly perfect and efficient. In short, the recycling process and technology of new energy vehicles are important links in the development of the entire industry. Through reasonable measures and methods such as vehicle disassembly, battery recycling, powertrain disassembly, body material classification, waste disposal, recycling, and safety control, the recycling rate and safety can be effectively improved, and the harm to the environment can be reduced. In the future, with the lack of progress in technology and the continuous deepening of application and promotion, the recycling process and technology of new energy vehicles will become increasingly perfect and efficient.